In the fast-paced world of packaging, efficiency and precision are paramount. For industries focused on high-volume production, technological advancements have transformed packaging lines, ensuring consistency, safety, and speed. Two such innovations that have become game-changers are the continuous motion vertical form fill seal and the multihead weighers machine. These machines are revolutionizing packaging processes, making them more streamlined and effective.

Improving Packaging Efficiency and Speed

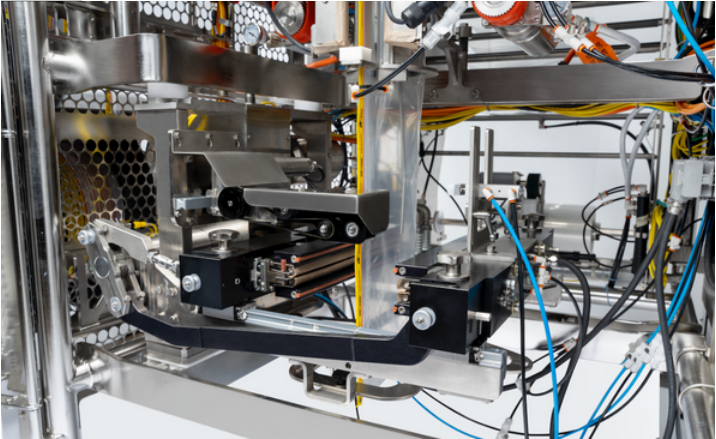

The packaging industry relies on machinery to meet growing consumer demands for speed and quality. The continuous motion vertical form fill seal machine is designed to maximize efficiency by continuously operating without interruption. This technology allows for the vertical formation, filling, and sealing of bags or pouches at high speeds. The process is seamless, providing an edge over older, slower systems. The result is reduced downtime, improved productivity, and an overall boost to packaging line efficiency.

Multihead Weighers and Precision

The precision of packaging is just as crucial as speed. This is where the multihead weighers machine plays a significant role. Used in combination with the vertical form fill seal, multihead weighers ensure that each package is accurately filled with the right quantity of product. The machine uses multiple weigh heads that measure portions of the product simultaneously, providing a precise weight for each package. This technology not only improves accuracy but also ensures that waste is minimized and products are packaged efficiently.

Features and Benefits of Continuous Motion

One of the main advantages of the continuous motion vertical form fill seal system is its ability to adapt to various packaging types and sizes. This versatility is especially important in industries such as food, pharmaceuticals, and cosmetics, where packaging requirements can differ. The continuous motion allows the machine to run smoothly at high speeds without interruption, making it ideal for high-demand production lines. It also reduces the need for frequent adjustments, lowering maintenance costs.

How Multihead Weighers Improve Packaging

The multihead weighers machine offers several benefits when incorporated into a packaging line. By measuring products simultaneously with multiple weigh heads, the machine optimizes the filling process. The multihead weighers allow for quick adjustments, ensuring that even delicate products are weighed and packaged correctly. Moreover, the system is highly adaptable, and able to handle a wide range of products, from solid snacks to powders. This flexibility is essential in industries where product variety is key.

Innovation and Sustainability in Packaging

Packaging machines like the continuous motion vertical form fill seal and multihead weighers machine not only drive efficiency but also contribute to sustainability. The precision offered by these systems means less product waste, and fewer errors, reducing both the cost of raw materials and the environmental impact. Additionally, these machines can work with biodegradable and eco-friendly materials, further supporting sustainability goals. In an era where sustainability is a growing concern, these advancements offer manufacturers a way to meet environmental challenges.

The Future of Packaging Machinery

As industries evolve, so does the technology behind packaging machinery. Future advancements in the continuous motion vertical form fill seal and multihead weighers machine will likely include AI integration, enhanced automation, and even more eco-friendly solutions. The industry is leaning toward smarter machines that offer real-time data, predictive maintenance, and self-adjustment capabilities. These innovations will continue to improve packaging accuracy, speed, and sustainability.

Conclusion

Incorporating advanced machinery like the continuous motion vertical form fill seal and multihead weighers machine is crucial for businesses aiming to stay competitive in the packaging industry. These innovations enhance efficiency, reduce waste, and ensure high-quality standards. With continued technological development, packaging solutions are set to become even more intelligent and sustainable. For more details on the latest trends in packaging technology, visit the domain where innovation meets excellence.